Sherline 2000 CNC - Part 2

Sherline Pages Home : << Part 1 : Part 3 >>

I replaced the z-axis with a 3A version of the driver board. It's still driven by the same 24V 1A supply. Eventually, I'll put a higher voltage/amperage supply on that axis.

Also I added an "enable" switch to the board. Pushing it back turns off the z-motor. Handy for doing a test run without the end mill going down into the workpiece.

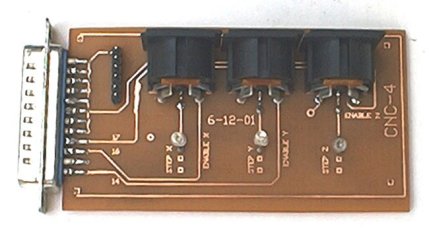

The more significant change is that I made another interface board.

I know, it looks similar to the old one, but the control lines that go to the driver board enable inputs are different. The three axii are enabled/disabled independently via the control port bits C1, C2, and C3.

I modified Stepster to enable only the drivers that are necessary for the specified line of g-code. It makes an incredible difference in keeping the motors cool!

12-2-2001

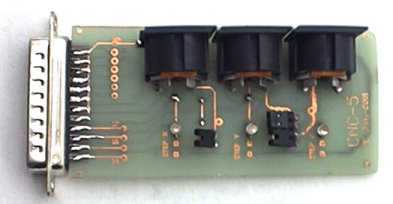

Another day, another breakout board! I started using EMC, and EMC uses yet another pinout.

I have to dive into the EMC source code and see how to add automatic axis enable to it. But that has to wait until I get a computer to dedicate to Linux/EMC.

|

|

|

Fun with Delrin!

Delrin is Dupont's brand-name for Acetal. It's an easy-to-machine plastic. Doesn't melt, cuts smoothly, very strong. Costs a fortune (stocked by McMaster-Carr). The only problem I had was figuring out how to hold it down while milling. Tried double-sided tape, which was messy and unreliable. Ended up sandwitching the Delrin between an aluminum template and a 1/4" aluminum backplate. Works great! The cutting has to be done in two passes, otherwise the piece moves around too much. |

|

As an Amazon Associate I earn from qualifying purchases [ Home

|

| Sherline Pages Home

] |

||