Sherline 2000 CNC - Part 1

Sherline Pages Home : Part 2>>

The shiny box contains the microstepping Y-axis driver. There's one for the X-axis as well. The motors are dual-shaft 53oz steppers.

The maximum x-y unloaded speed is about 1" every 5 secs (12" minute).

As I'm not concerned about chips flying onto it, the z-axis microstepping driver is mounted on a metal plate sandwiched between the motor and the mill. The heat-sink makes it look cool, but the driver chip would not overheat without it (the x-y drivers do not have heat sinks on them).

Maximum z-axis speed is slightly slower then x-y speed, especially going up.

Three axii, three power supplies! The two on the left are standard linear supplies used on the x-y axii (the middle one is 17V). The z-axis is driven by a 24V 1A switching power supply. All are plugged into a power strip with a master on/off switch, which serves as the emergency stop switch.

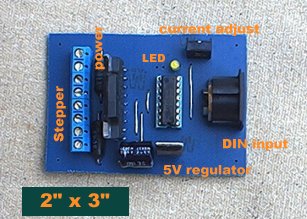

The microstepping drivers look like this, although now a standard power jack is used.

Rated for 1.5A, I haven't managed to break one yet. They have a disable input which turns off power to the motor. Very helpful for keeping the motors and drivers cool.

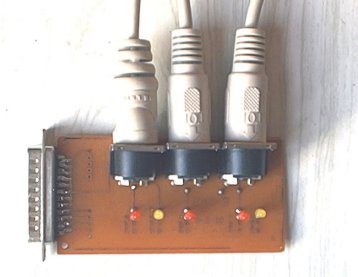

This 'breakout' board distributes the step/direction/enable signals to the microstepping driver boards.

It's a double-sided board that plugs directly into the parallel printer port. The red LEDS show STEP signals, the yellow LEDS are the ENABLE signals. M9/M8 is used to enable/disable current to the Z-axis stepper, M5/M3 is used for the x-y axii.

|

|

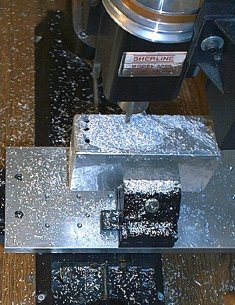

Making chips! A ball-end mill drills three holes, then mills out a rectangular hole on a die-cast box.

The setup is currently driven by Stepster.

Sherline Pages Home : Part 2 >>

As an Amazon Associate I earn from qualifying purchases

[ Home

|

| Sherline Pages Home

]