Sherline 2000 CNC - Part 4

Sherline Pages Home : << Part 3 : Part 5 >>

6-25-2002

Fun with Power supplies.

Decided to upgrade my power source somewhat, so I started

using this supply.

It came out of a DECPrinter, of 1980s vintage. It gives me 2

24V outputs at plenty 'o amps.

|

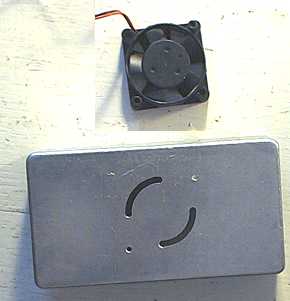

I was having a problem where the driver ICs were overheating when doing slow moves. Solution? Cooling fans liberated from Pentium heatsinks and a little G02 action on the top of the stepper driver box. The airflow has eliminated my driver chip overheating problems. They look 'cool' as well. |

12-10-2002

|

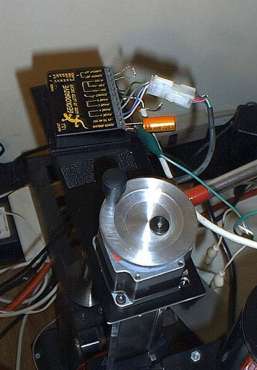

To recap the setup so far, there are 55 oz-in motors on all axii. I run X and Y with a rapid of 15 ipm, Z set slightly slower. When the mill is adjusted and lubricated properly, it will reliably travel faster. However, 15 ipm is a conservative setting to allow for a 'safety margin'. X and Y share a 24V power supply, Z has two supplies for a total of 41 volts (the maximum for the Allegro SLA7042 driver IC is 46V). Driver for all three axii is a microstepping, chopping unipolar-style (not to be confused with those cheap 4-transistor unipolar drivers). For some Z-axis experimentation, I got a Gecko G201 bipolar driver, a 48V switching supply, and a low-inductance 3A Vexta motor. The motor is small, about the same size as the 55 oz-in motor, but square instead of round. After removing the handleweel (it was making the whole mill shake), I was able to achive 60 ipm rapid on Z! Yes, 1200 rpm. Very fast! And there was still some torque at that speed. I couldn't stall the motor by pressing down on the headstock as it was rising. If I keep this on Z, I will probably limit it to 28-30 ipm, both to have a safety margin, and also so the mill doesn't shake itself apart. |

As an Amazon Associate I earn from qualifying purchases

[ Home

|

| Sherline Pages Home

]